what does 12 to 1 compression is how much psi

One-thousand horsepower, four-cylinder engines are today's reality in import drag racing. This reality includes the leading-border forced induction and engine-management technologies that make power product the easy office of building a racecar. Today's performance engines are running at higher boost pressure levels and college compression ratios than ever before. Understanding how both compression ratios and boost pressures affect performance is a key to maximizing performance from your street or race vehicle.

By Michael Ferrara // Photos by DSPORT Staff

DSPORT Issue #125

iv-stroke Engine Nuts

Without going into a lengthy caption of internal combustion engine dynamics, your vehicle'due south engine is a automobile designed for energy conversion. Using a four-stroke wheel, a fuel-and-air mixing strategy and a spark for ignition, the internal combustion engine's first job is to convert the chemical energy stored in the fuel into thermal energy (heat) through a process chosen combustion. The engine's second task is to convert this thermal energy into kinetic energy in the form of horsepower at the flywheel. How well an engine can catechumen the heat (thermal energy) into power (kinetic energy) is quantified past an engine'south thermal efficiency. An engine's thermal efficiency is highly influenced by the engines static pinch ratio. [pullquote]THE BALANCE OF Boost VERSUS COMPRESSION RATIO HAS BEEN AN ENGINE Architect'S AND TUNER'S Challenge FOR YEARS[/pullquote]

Compression Ratio

Every bit the name indicates, the pinch ratio of an engine indicates how much the air-fuel charge is compressed during the compression stroke of the four-stroke process. A 10-to-one compression ratio means that the air- fuel mixture gets squeezed down from the full volume of the cylinder to a volume that is just roughly one tenth of the cylinder's size. So how does an engine's compression ratio affect performance? All other factors being equal, an engine with a higher compression ratio volition evangelize a higher thermal efficiency. This means that the engine is able is turn more than of the heat generated from the combustion procedure into horsepower instead of wasted heat. In bones terms, college thermal efficiencies interpret into boosted horsepower and better fuel economy.

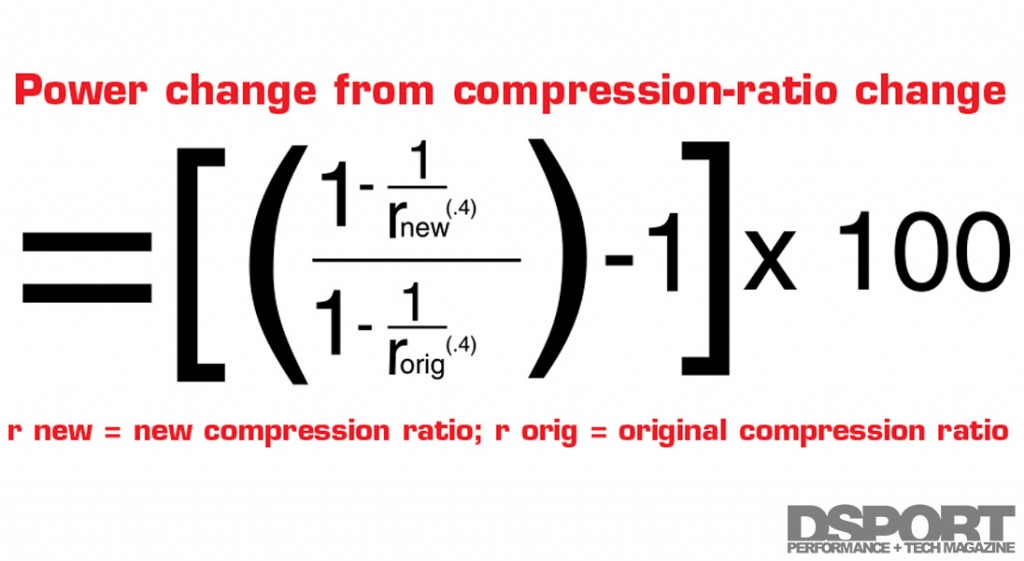

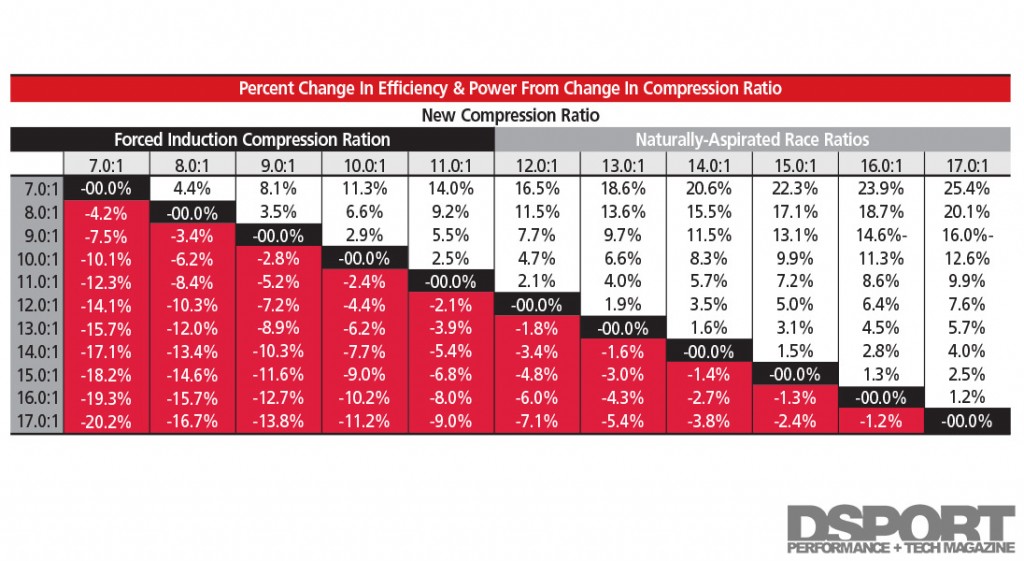

How much additional power can be expected with a higher compression ratio? The old-school rule of thumb is that each additional point that the compression ratio is raised will deliver an additional four percent ability. In fact, more accurate projections can be found in the accompanying DSPORT chart. These values were obtained using the thermodynamics equation to found the thermal efficiency of an Otto bicycle engine.

Plugging through this equation we detect an increase in compression ratio from eight.0:1 to eleven.0:1 should event in a ix.ii-percentage increase in ability. Too a reduction in compression ratio from 11:1 to 7.0:1 should result in a 12.3-per centum subtract in power.

Believe it or not, high-compression engines of the tardily '60s, with pinch ratios up to 12.5:1, had college thermal efficiencies than many of today'southward engines. For the same size engine, the older engine would accept been more fuel efficient if they had the fuel, cylinder caput and ignition technologies of today combined with the high-octane gas of the 60s.

Boost Pressure

In dealing with naturally-aspirated applications, high compression ratios are the cardinal to serious ability levels. In dealing with forced-consecration applications, it's well known that increasing boost pressure on a properly sized turbocharger volition increase power product (at to the lowest degree, to a point when the capacity of the turbo or fuel system is exceeded). Of grade, the large downside to higher boost pressures is that the likelihood of encountering engine- damaging detonation also increases.

In dealing with naturally-aspirated applications, high compression ratios are the cardinal to serious ability levels. In dealing with forced-consecration applications, it's well known that increasing boost pressure on a properly sized turbocharger volition increase power product (at to the lowest degree, to a point when the capacity of the turbo or fuel system is exceeded). Of grade, the large downside to higher boost pressures is that the likelihood of encountering engine- damaging detonation also increases.

The balance of boost versus compression ratio has been an engine builder'south and tuner's challenge for years. Picking up a copy of one of the 60'southward- technology forced-induction manuals will highlight their solution. The higher the boost pressure, the lower the pinch ratio of the engine. For "serious" race forced-induction setups pinch ratios of vii.0:one were not uncommon.

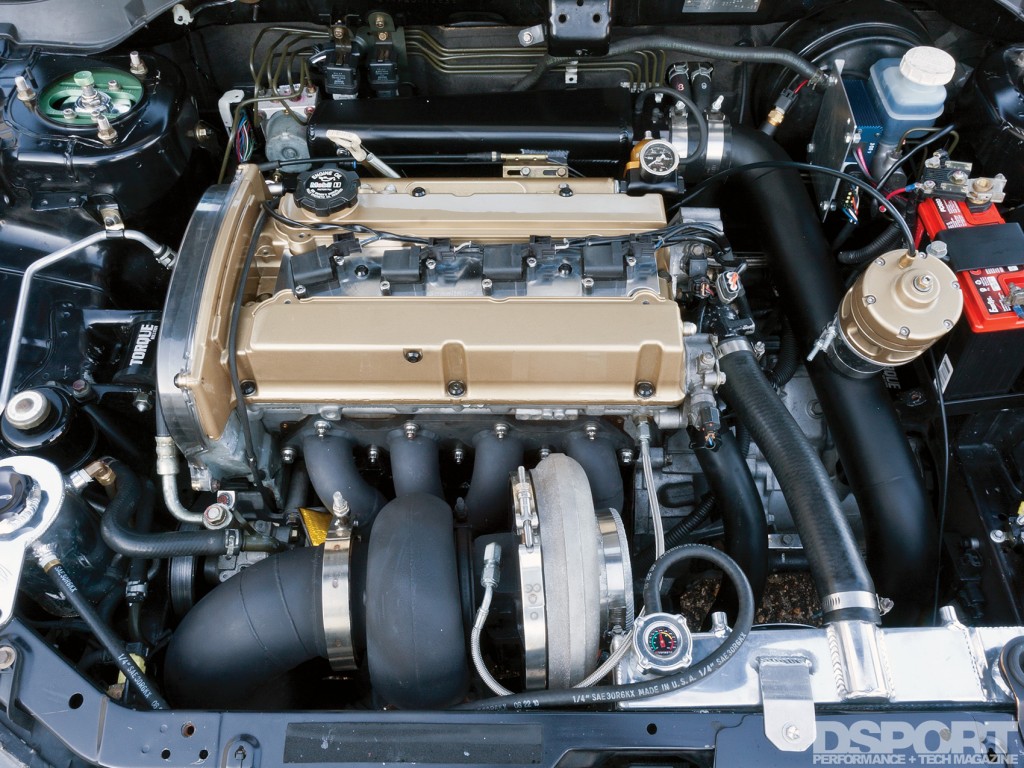

Fortunately, poor manifold and fuel delivery designs, every bit well every bit low-efficiency "blowers," are not establish on likewise many of today'due south popular performance vehicles. Today, the average high-performance street or strip turbocharged four-cylinder race engine sports a compression ratio of 9.v:1, with some even running pinch ratios equally high equally xi.5:1 or more than on alcohol or E85. Modernistic technology allows our racing generation to get the best of both worlds. Loftier boost pressures with loftier compression ratios.

Fuel and Detonation

Octane & Knock

The octane rating indicates the likelihood of the fuel to feel "knock." Knock, the audible audio given to the status, also goes past the names of detonation. Knock is detrimental to performance and reliability and information technology needs to be avoided. Knock occurs when the fuel-air mixture in the cylinder doesn't feel an ideal burn (the procedure of combustion). An platonic burn allows the mixture to combust evenly initiating from the spark plug until all of the air-fuel mixture occurs. In a laboratory environment, the ideal burn will occur at almost 100 feet per second in a vacuum. In the turbulence of an engine's combustion chamber, good flame speeds may be up to 250 feet per second. During detonation or knock the burn rate will run into a violent 2000 feet per 2nd explosion instead of a burn. Burn rates are crucial to how pressure builds in the cylinder. [pullquote]Superlative CYLINDER PRESSURES TEND TO RISE AS Pinch RATIO, VOLUMETRIC EFFICIENCY, IGNITION Accelerate AND BOOST Force per unit area Rising[/pullquote]

The called-for of the air-fuel mixture results in a pressure increment. Ideally, pressure builds in the cylinder at the optimum time reaching a peak pressure somewhere betwixt 17 to 20 degrees afterwards top dead heart. This allows the cylinder pressure to produce the most horsepower at the crank. When knock occurs, the pressure cycle within the cylinder doesn't occur as desired. In fact when knock occurs, the original flame front and pressure moving ridge from the desired spark-ignited front meet an undesired motorcar-ignited flame front. When these two pressure waves meet, the pressure level oscillations produce a "knocking" audio. When knock occurs, power is reduced, while rod bearings, connecting rods, head gaskets and pistons may suffer slight damage or catastrophic failure depending on the severity of knock. Elevated temperatures mostly upshot from knock and this can atomic number 82 to preignition problems that crusade the air-fuel mixture to ignite fifty-fifty before the spark fires.

Knock or detonation is not the same as preignition. Pre-ignition occurs when the air-fuel mixture becomes ignited earlier the spark plug fires. Sometimes elevated temperatures or a hot spot in the cylinder can cause preignition. While both knock and preignition crusade undesired burns of the air-fuel mixture, the difference between the ii is elementary. Knock or detonation occurs afterward the air-fuel mixture has started its fire, preignition occurs earlier. Both produce undesirable pressure waves that affect functioning and can translate into engine harm.

Need for Higher Octane

If your engine is experiencing knock, you'll need to run a higher-octane fuel or retard ignition timing. The need for fuels with a higher octane rating generally occurs as peak cylinder pressures rising. Top cylinder pressures tend to rise as compression ratio, volumetric efficiency, ignition advance and boost pressure rise.

The general rules are simple. Naturally-aspirated engines will demand a higher- octane fuel as either pinch ratio is increased or ignition timing is advanced. Forced induction engines respond the same, but will besides demand college octane as boost pressures increase.

You lot may have heard the following: "don't apply too loftier of an octane fuel or you will lose power." This is a half-truth. Having a fuel with likewise high of an octane will not make your engine lose ability. However, having a fuel with a burn rate that is likewise slow tin make your engine lose ability. In general, the popular components used to make the octane of a fuel higher also boring the burn charge per unit. Of course, that is but a generality and it doesn't hold true for all fuels.

Alternative Fuels: Methanol & Ethanol

Methanol has been used equally an alternative racing fuel to race gas for a number of years. One advantage of methanol is that it can be run very rich without a meaning drop in power. This can permit the tuner to use the fuel as a cooling tool in the tuneup. Withal, methanol packs merely about half of the energy constitute in gasoline. Fortunately, you lot can burn nearly twice the mass of methanol compared to gasoline for the aforementioned amount of air. Depending on whom y'all ask, zero to ten percent more power tin be made with methanol over racing gasoline.

In that location are meaning tradeoffs for the ability gains. First, methanol is highly corrosive. The entire fuel system must be methanol compatible and even and so y'all will probably feel corrosive issues. It'south best to affluent the system of methanol at the completion of the race. Methanol also requires twice the fuel delivery and storage capacity of gasoline. Your fuel cell or gas tank will either need to double in size or you'll only be able to travel half equally far. Injectors and fuel pumps will demand to accept twice the menstruum capacity of a gasoline setup likewise.

Ethanol or ethanol-blends like E85 are now more than popular than ever for street and racing employ. Ethanol is the aforementioned type of alcohol found in alcoholic beverages. To avoid legal problems, manufacturers alloy 98 percent ethanol with two per centum gasoline to produce E98 or 85 per centum ethanol with 15 per centum gasoline to brand E85. The advantage of ethanol is that it does non take the corrosive issues that yous observe with methanol. Even so, information technology does have a lower free energy content than methanol. The Venom Racing squad became the first import elevate racers to run in the 6s running on ethanol every bit a fuel.

Dished pistons (front)are most mutual on lower-compression engines, while domed pistons (rear) tend to appear in higher compression engines.

Dished pistons (front)are most mutual on lower-compression engines, while domed pistons (rear) tend to appear in higher compression engines.

17:1 Compression Ratio and 45psi Boost Pressure

No. Don't go out at that place and attempt to build a 17:one pinch ratio race engine with the boost pressure cranked upwardly to 45psi. Every bit the tardily Gene Humrich of Centerforce Clutches used to ever say, "For every action, at that place's going to exist a reaction. And if the repercussions of the reaction are worse than the benefits of the action, you are going to go screwed." So what is the reaction to the activeness of raising your pinch ratio on a forced induction awarding? A combination of as well much heave or as well much compression will increase the likelihood of detonation.

So how much pinch ratio should you lot run for a specific amount of heave pressure? It depends primarily on iii factors. Fuel quality, intercooler efficiency and the tuning state (how well the fuel bend and ignition curves are set) of the engine. Methanol or E98/E85 engines volition allow higher compression ratios than racing gasoline. Better intercooler systems will also allow higher compression ratios. Some tuners can optimize the engine despite having the narrower tuning window of a higher-compression/high-boost application. In the end, engine development is the simply fashion to get the answer to the question of the perfect compression ratio and boost pressure.

Looking back nearly fifty years agone, Chevrolet reigned supreme when its ultra- high-operation, 283-cubic-inch small block generated an unprecedented 283 horsepower—one horsepower per cubic inch. Loftier compression pistons, a racing-profile solid-lifter camshaft and a pair of 4-butt carburetors made the incommunicable possible. Today, high output variable-cam-timing engines from Honda and Toyota generate nearly twice that effigy with outputs approaching 2.0 horsepower per cubic inch. Double-overhead camshafts, four-valves-per-cylinder, calculator- controlled valve timing, advances in cylinder head blueprint and electronic fuel injection take credit for the advances in naturally-aspirated ability output.

Technology is e'er developing and new rules supersede old rules when it comes to operation. However, the relationship among compression ratio, boost pressure level, detonation and fuel octane is one that will always remain. Understanding this human relationship allows tuners to setup an engine to maximize performance for a given fuel quality.

Source: https://dsportmag.com/the-tech/boost-vs-compression-benefits/

0 Response to "what does 12 to 1 compression is how much psi"

Enregistrer un commentaire